Industry 40which includes connectivity advanced analytics automation and advanced-manufacturing technologies Exhibit 1was gaining momentum before COVID-19 helping companies transform their operations in everything from production efficiency to product customization with improvements in speed to market service effectiveness and new-business. The Theory of Constraints ToC is an idea from the world of physics that was brought into manufacturing management by Eli Goldratt in his book The Goal 1984.

Capacity Planning An Industry Guide Plex Demandcaster

Capacity planning and techniques will function differently depending on production mode.

. There are three main types of capacity planning that you need to be aware of before you get started. Determining capacity requirements analyzing current capacity and planning for the future. More advanced than standard MRP.

Workers at Qcells 17GW module assembly plant in the US state of Georgia. A rough cut planning is usually done at the master schedule level and this is used for short-term planning may be for a week to two months. As these operations often have complex multi-level BOMs.

Practical examples of models in capacity planning for different production modes include. But this is the trajectory for US manufacturing in 2022 emerging from the pandemic. Planning for capacity breaks down into three steps.

1313 EAST 60TH STREET CHICAGO 37 ILLINOIS. Resource capacity planning Resource capacity planning at a high level is simply a calculation of number of employees multiplied by expected billable hours available in a given week. Two terms of design capacity and effective capacity are used extensively in the context of capacity planning.

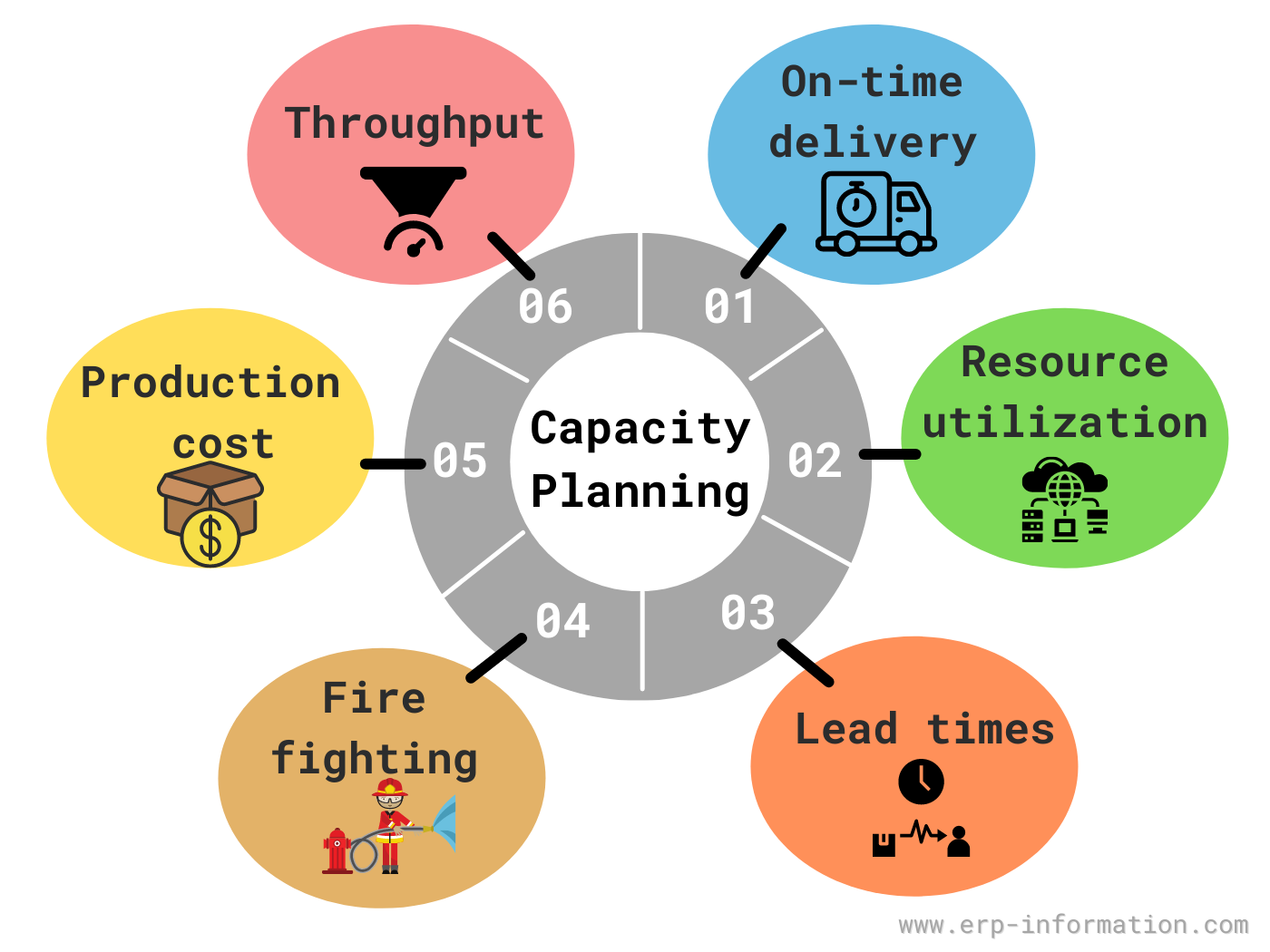

Advanced Scheduling functionality considers the availability of resources and additional constraints such as tooling and materials to ensure an accurate model of the manufacturing environment. You can analyse capacity and test different scenarios to answer what if questions and identify issues before they occur. With regard to the manufacturing industry the process of Capacity Planning is made up of three resource types.

The 3 types of capacity planning. One or more of these types of resources are used to perform an operation on a job. Machines people and tools.

AMERICAN SOCIETY OF PLANNING OFFICIALS. Project capacity planning Project managers estimate the amount of time their assigned team can work in a given timeframe to balance workloads against project delivery. Production plans can be changed quickly and easily and are visible to the right people at the right time.

Industry-specific features like job costing and work-in-progress reports are also included. The Automotive News mission is to be the primary source of industry news data and understanding for the industrys decision-makers interested in North America. 2022 manufacturing industry outlook Manufacturers eyeing growth It is unusual to see positive economic indicators paired with historic labor and supply chain challenges.

When you dont know the production capacity your production planning is like taking. Medium or aggregate planning uses a 12-18-month planning window to provide a longer view that allows the organization to ensure that demand can be. Contact Us 1155 Gratiot Avenue.

Tecnomatix is a comprehensive portfolio of digital manufacturing solutions that help you to digitalize manufacturing and the process of turning your innovative ideas into transformative products. Make to Stock MTS Make to Stock is common within discreet manufacturing and process manufacturing. Capacity planning for production is relevant to the product demandsupply concept.

Having a plan in place will ensure that you have the. The first is the maximum work that is completed in a specific period by an organization and the latter is the. Industry 40 in a nutshell.

The purpose of production capacity planning tools is to assist the sales team to ensure the companys ability to fulfill customer demand. Manufacturing planning and scheduling software helps production managers by using mathematical models to better simulate and understand the production environment. The US could exceed 50GW of solar manufacturing capacity by the end of this decade with the right.

To gain a better grasp on how each applies to the planning process let us take a closer look at each one individually. The recovery gained momentum in 2021 on the heels of vaccine rollout and rising demand. This is where you get an overview of your entire business from how much work you can do to how much you can take on at any given point.

This is the only way to anticipate how much of each resource you will need in order to create X amount of products. Manufacturing Production Planning and Scheduling Software. We hope you enjoy this fascinating snapshot of a planning issue of yesteryear.

Capacity planning means knowing the maximum capacity your operation can managethe absolute most of a product or service it can offer during a period of time. Industry 40 IIoT and digitisation are currently some of the most-discussed and yet least understood topics within manufacturing today. However modern planning engines like advanced planning systems or APS plan material and capacity simultaneously thereby recognizing the finite nature of capacity.

With still a lot of confusion surrounding Industry 40 today well be exploring the key technologies behind Industry 40 as well as real-world applications. The purpose of this information is to detail the arrangements for delivering industry placements through the CDF for those providers in receipt of a CDF allocation in 2020 to 2021. Access production planning software ensures that you are utilising every machine employee and resource to its full capacity.

In most manufacturing environments capacity planning is often done at different levels. Download original report pdf At the end of World War II an era of unprecedented industrial expansion opened in. The first step of capacity planning is to.

So the supply chain managers focus on effective capacity planning in the production process of supply chain management. Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization. Planning can be executed in finite or infinite capacity mode and planning time periods can be days weeks months or a combination of all three.

With Tecnomatix software you achieve synchronization between product engineering manufacturing engineering production and service operations to maximize your efficiency. For planning purposes manufacturers want to know how many hours in a said week or month would each of these resource.

What Is Capacity Planning Strategies Tools And Process

Production Capacity Calculation Template Capacity Planning Capacity Historical Data

Capacity Planning Template Example Elegant 7 Resource Capacity Planning Template Excel Capacity Planning How To Plan Excel Templates

Best Manufacturing Planning Software For Manufacturing In 2021 How To Plan Planning Maps Capacity Planning

0 Comments